The patent relates to a “flexible” electrical connector for connection to an electrical element on a substrate such as glazing in a vehicle.

Brief outline of the case

Opponent 1 appealed the decision of maintenance according to AR3.

The board decided to revoke the patent as the subject-matter of claim 1 as maintained and of AR1 was lacking IS over E1=DE 103 01 352 + D3=US 5,920,125. AR 2 had a problem of clarity.

The OD’s position on IS

The OD’s main argument in favour of IS was that the skilled person confronted with the objective technical problem could have consulted a skilled person in the field of electronics and solder connections of chips to circuit boards.

However, according to the OD the skilled person would not have applied the solution of document D3 to the vehicle glazing of document E1 in view of the different materials and dimensions of the vehicle glazing compared to a circuit board and in view of an electrical connector with first and second connection portions compared to a semiconductor chip.

The opponent’s position

The opponent argued that a particular degree of flexibility of the electrical connector could not be derived from claim 1. The term “flexible” in the overall context of claim 1 can thus at most be understood in functional terms as meaning that the electrical connector must be sufficiently flexible for a connection to a (possibly curved) glazing. This is in accordance with the description in paragraphs [0013] and [0022] of the patent.

The proprietor’s position

The proprietor argued that “flexible” implies that the electrical connector has a higher degree of flexibility than the average connector. This argument did not convince the board. In particular, it is not at all clear what the “average flexibility” is, and the proprietor did not provide any further explanations in this regard.

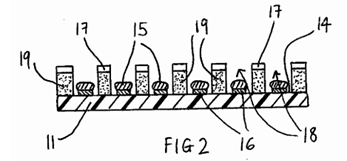

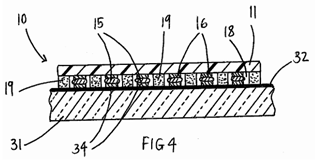

The proprietor also argued that in the case of the connector according to the patent, the greater degree of flexibility was achieved by the use of a connector body 11 which comprises a single foil of a suitable plastic, together with an adhesive which adds very little in terms of stiffness. The board is not convinced by the respondent’s argument, because this specific structure of the electrical connector is not defined in claim 1.

The proprietor further argued that in the case of the connector according to the patent, the greater degree of flexibility was achieved by the use of a connector body 11 which comprises a single foil of a suitable plastic, together with an adhesive which adds very little in terms of stiffness.

In favour of IS, the proprietor essentially argued that the skilled person would not have considered the remote and highly specialised technical field of interconnection structures for joining a semiconductor device to a chip carrier when seeking solutions to the objective technical problem relating to the glazing of a vehicle.

The board did not agree with the respondent that the skilled person would not have considered document D3 when seeking a solution to the objective technical problem. The opponent has correctly argued that document D3 refers to an electrical connector in the form of a semiconductor chip.

The board’s position

Lack of clarity

The board held that claim 1 as maintained suffered from a significant lack of clarity, since the claimed vehicle glazing was defined by features of the electrical connector which, however, refer to a status prior to connection to the vehicle glazing.

Claim 1 is contradictory in that, on the one hand, it refers to a vehicle glazing comprising the electrical connector, which is electrically connected to an electrical element of the glazing material pane and adhered to a surface of the glazing. This clearly implies that the electrical connector is firmly attached to the glazing. According to paragraph [0022] of the patent, this is done by using a heating tool which ensures a substantially uniform thickness of the conductive material and of the adhesive.

On the other hand, according to feature 1-l of claim 1, each of the areas of conductive material (15) on the first connection portion has a thickness that is less than the thickness of the adhesive (19). This is in clear contradiction to the final (connected) state of the electrical connector, where the conductive material and the adhesive have a uniform thickness.

Therefore as stated in paragraph [0022] of the patent, feature 1-l has to be interpreted such that it refers to a state of the electrical connector, and in particular of its first connection portion, which is prior to the application of the heating tool to the first connection portion.

In spite of the “overall” lack of clarity, the board was not convinced about the argument on flexibility as it was not at all clear what the “average flexibility” could be. The proprietor did not provide any further explanations in this regard.

The board was also not convinced by the proprietor’s argument, because the specific structure of the electrical connector was not defined in claim 1.

Lack of IS

Notwithstanding the various problems of clarity, the board was able to conclude on the lack of IS of the patent as maintained.

Document E1 does not directly and unambiguously disclose either that the adhesive may be provided on the functional surface of the connector, or that the adhesive is formed around each (and not all) of the areas of conductive material.

For the board, the objective technical problem, when starting from E1 and having regard to the distinguishing features, can be considered to be at least that of how to provide a vehicle glazing comprising an electrical connector which prevents short circuits and splashing of conductive material during and after connection of the electrical connector to the vehicle glazing.

The board did not agree with the proprietor that the skilled person would not have considered document D3 when seeking a solution to the objective technical problem.

The electrical connector referred to in claim 1 as maintained does not have any features which are so specific to vehicle glazing that a person skilled in the art, when seeking a solution to the objective technical problem, would restrict their search to the field of vehicle glazing or electrical connectors specifically for vehicle glazing.

Rather, it would be immediately apparent to a skilled person that the objective technical problem in the case at hand is not specific to vehicle glazing, but may clearly concern other technical fields involving an electrical connector that is applied to a substrate. The skilled person would therefore naturally look to other technical fields which are promising in the sense that they might provide solutions to the objective technical problem.

Electrical connectors for connecting semiconductor chips to substrates may be of different dimensions and also may imply the use of different materials, as found by the OD. However, the principles used there can also be applied in a general way to the area of vehicle glazing comprising electrical connectors. The person skilled in the art would recognise this immediately and include the relevant technical areas in the search for solutions to the objective technical problem.

In order to do this, the skilled person would not have to be an expert in these other technical fields. The skilled person clearly has sufficient knowledge in the field of the electrical aspects of vehicle glazing with regard to solder connections, which would allow him to understand corresponding developments in other fields of technology as well.

The board therefore concluded that claim 1 as maintained lacked IS when combining the teachings of E1 and D3.

Comments

In T 176/84, OJ 1986, 50, the board concluded that, when examining for IS, a skilled person would consider the state of the art in the specific technical field of the application, look for suggestions in neighbouring fields or a broader general technical field if the same or similar problems arose, and if he could be expected to be aware of such general fields.

In the present case, it might at a glance look odd to combine the teaching of E1 which relates to a connector for glazing, with D3 which relates to the soldering of a chip on a substrate. On the other hand, D3 can be said to belong to a neighbouring field in which the skilled person could find a solution to its problem.

On the procedure

The patent should not have been granted in the form it was granted. The ISR established by the EPO mentioned no less than 4 documents of category X, but neither E1 nor D3 were mentioned in the ISR.

The present decision of the OD belongs to the nearly 60% of decisions set aside by a board.

https://www.epo.org/en/boards-of-appeal/decisions/t210568eu1

Comments

Leave a comment